Material Sourcing Hub

RAWMAT offers wide range of Refactory Products

Refactory

Tundish Refractories

Tundish Spray Mixes, Phosphorus Free Spray Mixes

Form: Powder/Mix

Application: Thermal insulation and anti-wear.

Refactory

Clinkered Magnesia

Clinkered Magnesia - MgO Content: >90%, Bulk Density: >3.1 g/cm³, Grain Size: 0-25 mm

Application: Basic lining for converters, EAF, and VOD furnaces; offers superior slag resistance

Refactory

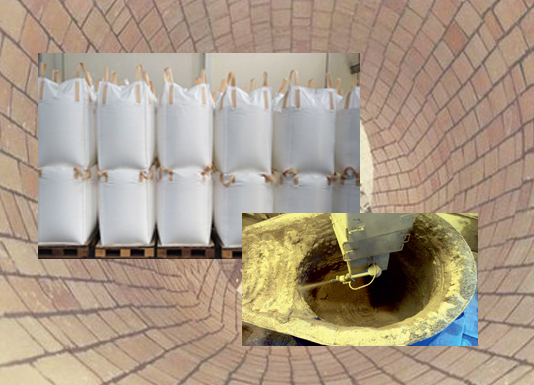

Gunning Materials

Gunning Materials - Chemical composition MgO, CaO, Al2O3

Form: Dry mix applied by gunning machines

Application: Repairs in furnace and ladle lining.

Refactory

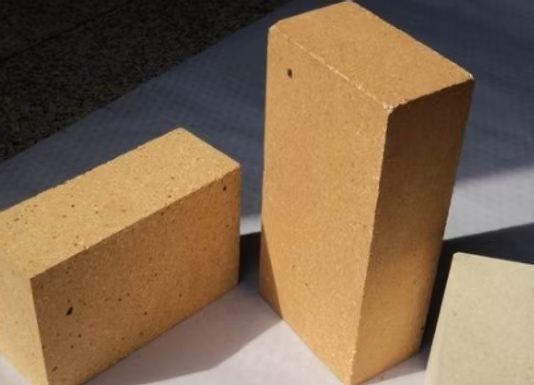

Ramming Mix

Material: Alumina, Magnesia, or Silica based depending on application

Grain Size: Up to 10 mm, Bulk Density: 2.2-2.7 g/cm³

Application: Used for permanent lining in induction furnaces, patching and bottom repair work.

Refactory

EBT Filling Materials (Olivine)

Composition: MgO.SiO₂ blend

Size: 0-10 mm, Bulk Density: 2.6-3.0 g/cm³

Application: Fills Electric Arc Furnace taphole to prevent slag blockage and ensure free tapping.

Refactory

EAF Fettling Material

Material: Alumina, Magnesia, or Silica based depending on application

Grain Size: Up to 10 mm, Bulk Density: 2.2-2.7 g/cm³

Application: Used for permanent lining in induction furnaces, patching and bottom repair work.

Refactory

Ladle Nozzle Filling Sand

Material: Chromite/Silica based Particle Size: 0.5-3mm Flow ability: High free-flow characteristics

Application: Fills the nozzle to prevent steel leakage and ensure smooth opening

Refactory

Refactory Materials

Connect with Rawmat Team to source best Refactory Materials.

Refactory Materials